Plastic / Rubber

Antimony glycolate (Sb₂(EG)₃) is an important catalyst in the polyester industry

Antimony glycolate (Sb₂(EG)₃) is an important catalyst in the polyester industry

Antimony compounds (especially antimony trioxide) are the core flame retardant synergists in the plastics industry. They work synergistically with other halogen flame retardants to form a protective layer that isolates oxygen, significantly improving the fire resistance of plastic products. For example

Widely used in flammable plastic products such as electronic and electrical housings, building materials, and automotive interiors to meet fire safety standards.

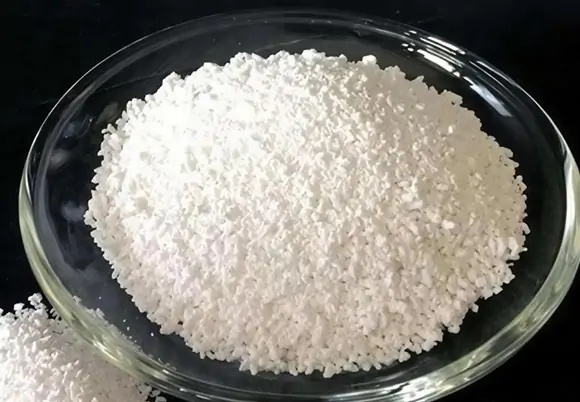

Sodium pyroantimonate is used as a flame retardant enhancer for plastic and rubber products to improve the high temperature resistance of materials.

Antimony-based flame retardants are irreplaceable because their effectiveness and insulation ability are superior to other inorganic flame retardants, although the cost is higher.

Antimony powder can be used as a plastic filler to improve the mechanical strength and corrosion resistance of the material.

In the production of polyester plastics (such as PET bottles), antimony compounds act as catalysts to accelerate polymerization reactions and improve material stability.

Antimony flame retardants are used in aerospace plastic parts (such as missile launcher insulation) to prevent high-temperature ablation and enhance the heat resistance of engine materials.

1%-3% addition can significantly improve the flame retardant performance without affecting the original physical properties of the plastic.

At present, no alternative materials with comparable performance have been found, especially in high-end fields (such as military industry and photovoltaic glass) where the demand is very rigid.

Flame retardants account for more than 55% of the world's total antimony consumption. As the largest antimony consumer, China's plastics industry is highly dependent on antimony resources.